About Cycle Counts

Digital inventories get out of sync with real world inventories all the time due to input errors and unreported changes. Cycle counts help you keep your MaintainX® parts inventory in sync with your real world inventory.

A cycle count is a reconciliation operation where you count real world parts to ensure the number in your MaintainX parts inventory matches the number you actually have on hand. Organizations usually conduct cycle counts on a scheduled basis in batches by last recount/criticality.

Cycle counts improve overall inventory management processes by helping you:

- Increase overall inventory accuracy.

- Identify and address discrepancies between your MaintainX parts and your physical inventory.

- Reduce errors caused by unreported changes and poor data input.

Cycle Counts Overview

The Cycle Counts Module

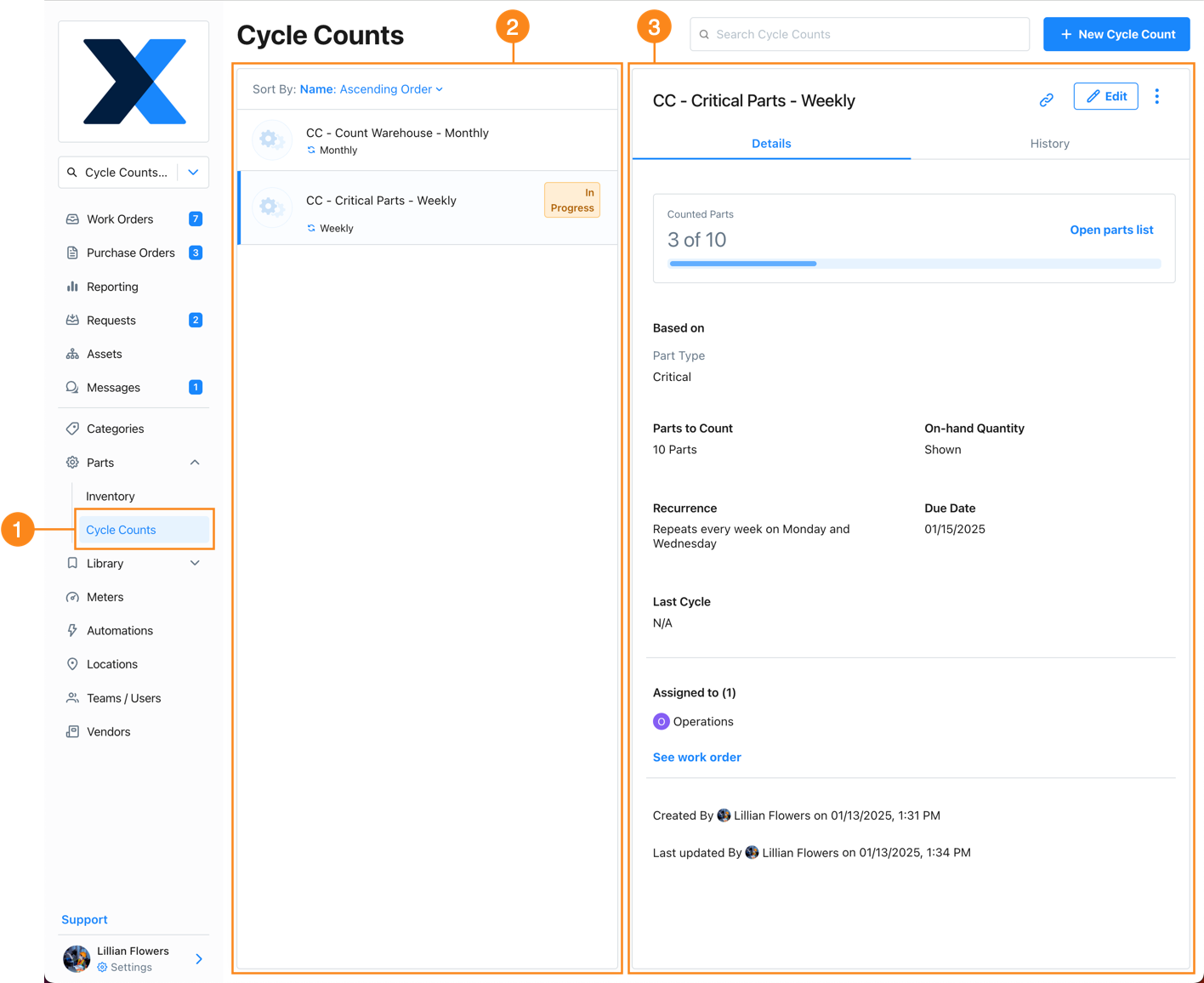

You create, schedule, and manage cycle counts from the Cycle Counts module, which you can access from the sidebar in the MaintainX web application. Select Parts > Cycle Counts.

- The Cycle Counts 1 module is available from the sidebar in the MaintainX web application.

- The list pane 2 shows all of your organization's cycle counts. Cycle counts marked In Progress have an active work order.

- The details pane 3 shows the cycle count's schedule, assignees, and other information. If the cycle count has an active work order, you can also see the progress here.

The Cycle Counts module is not available in the MaintainX mobile application. You can only create and schedule cycle counts in the web application. You can use either application to conduct a cycle count.

Cycle Count Work Orders

After you create a cycle count, MaintainX creates special work orders for each occurrence of the count. To conduct the cycle count, your teams execute the work order (see Conduct a Cycle Count).

You can't conduct a cycle count while in offline mode.

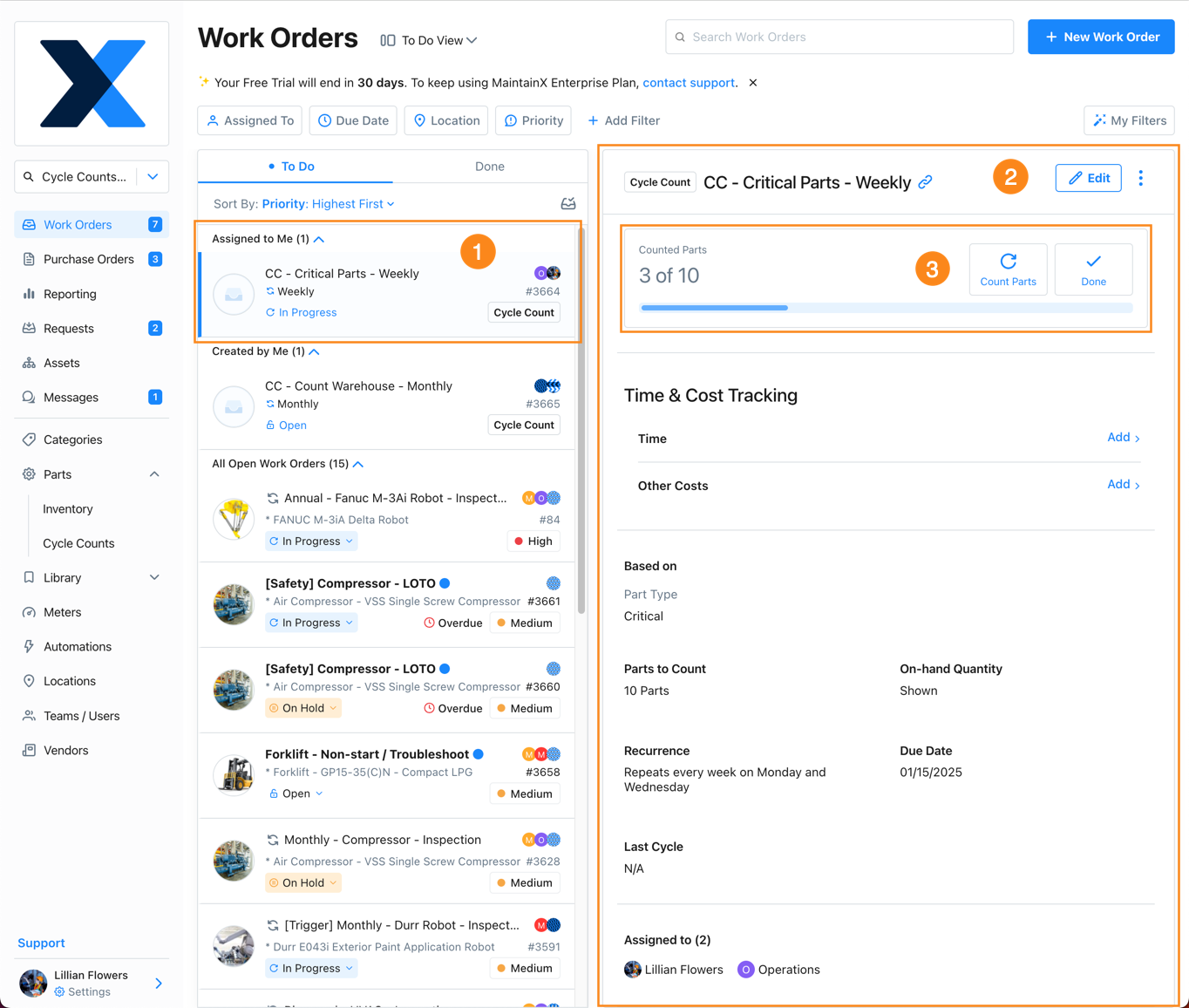

Cycle count work orders appear in the Work Orders module with the rest of your organization's work orders. But they only contain a subset of the information you find in a regular work order (as well as information that's specific to the cycle count), and they work a little bit differently.

-

MaintainX lists cycle count work orders 1 with your organization's other work orders.

Use the Work Type filter in the Split view or the Table View to see only cycle count work orders. Combine it with the Status filter to see only cycle count work orders that are open or in progress.

-

The cycle count work order details 2.

-

The Counted Parts options 3 where users can start, complete, and monitor the progress of a cycle count work order.

From any cycle count work order, you can access the cycle count dialog/screen where you can enter and view updated part counts. Each count is attributed to the user who enters the part quantity.

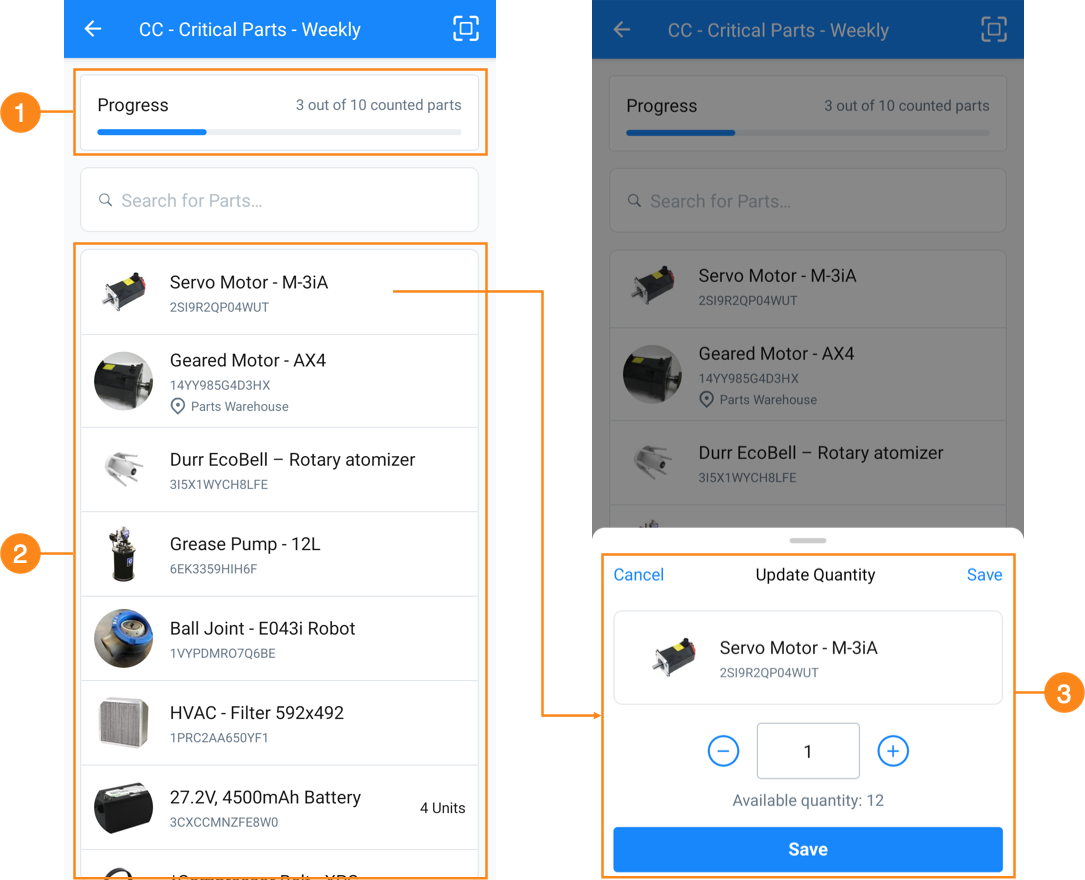

- The progress bar 1 shows the overall progress for the cycle count.

- The parts list 2 lists the parts to count.

- The count options 3 are where users enter the real-world count for each part.

Cycle Count Reports and Data

When you conduct a cycle count, you can see the progress in the corresponding work order, or in the cycle count entity in the Cycle Counts module. After you complete the cycle count, MaintainX creates a report with the results. You can view and export any report in a cycle count's history.

By default, cycle count work orders are also included in the work orders MaintainX uses for the work order reports in the Reporting Module.

For more information, see View Cycle Count Reports and Data.