About Work Orders

A work order is a standardized document that details a maintenance task or other work. It includes information such as:

- The asset that needs maintenance.

- The location where the work will happen.

- Who is responsible for completing the work.

- Which parts you need to do the work.

- When the work should start, and when it should be completed by.

- How long the work should take.

Administrators and Full Users can create and manage work orders for an organization. For more information, see Create a Work Order.

- Administrators can generate reports to get insights into their organization's work orders. For more information, see About Work Order Reports.

Types of Work Orders

Standard Work Orders

A standard work order details a maintenance task for a single asset or location, or some other work. You can create a standard work order from scratch or by using a work order template.

Multi-Asset Work Orders

For line-based maintenance, or maintaining multiple instances of the same asset, you can create multi-asset work orders. When you add more than one asset to a work order, MaintainX® creates a new work order for each asset.

- The original work order becomes the parent work order.

- The work orders for each asset become sub-work orders.

As you complete the sub-work orders, you can track the overall progress from the parent work order. For more information, see About Multi-Asset Work Orders.

Cycle Count Work Orders

Cycle counts help you keep your parts inventory in MaintainX in sync with your real world inventory. A cycle count is a reconciliation operation where you count real world parts to ensure the quantity in MaintainX matches the quantity you physically have on hand. You schedule cycle counts in the Cycle Counts module, and conduct them using a special type of work order that appears in your work order queue. For more information, see About Cycle Counts.

External Work Orders

An external work order is a shareable work order that you send to people outside of your MaintainX organization. They're useful for organizations that outsource work to 3rd parties. Recipients have limited access to shared work orders. For more information, see External Work Orders.

MaintainX CoPilot® in the Work Order Lifecycle

MaintainX CoPilot can be integrated throughout a work order lifecycle, from creation to completion. AI-supported work order features help accelerate, standardize, and simplify workflows, while continuously building an internal knowledge base which supports MaintainX CoPilot in providing accurate and tailored support over time.

While MaintainX CoPilot supports the creation and execution of work orders, your review and approval are always required.

MaintainX CoPilot helps you:

- Create work orders.

- Enrich work orders.

- Generate work order summaries.

- Create an internal knowledge base.

Create Work Orders

You can use MaintainX CoPilot to create work orders. In a MaintainX CoPilot-enabled asset's details, ask the AI assistant questions about your asset. From the answer, you can create a work order or a work order template.

When generating a work order, MaintainX CoPilot automatically adds the following:

- The asset's name in the Asset field.

- MaintainX CoPilot's answer in the Description field.

- The asset's files in the Files field.

MaintainX CoPilot accelerates the initial creation process of the work order, while giving you full control to review, finalize, and validate the work order. For details, see Create a Work Order from a MaintainX CoPilot Answer.

Enrich Work Orders

When you complete a work order with a MaintainX CoPilot-enabled asset, you can receive task-specific suggestions from MaintainX CoPilot. These suggestions are based on MaintainX CoPilot's answers, historical knowledge (e.g., past work order summaries), and documents uploaded to your assets.

MaintainX CoPilot can assist you by:

- Generating procedures. For details, see Attach an AI-Generated Procedure to an Existing Work Order

- Suggesting how to complete specific procedure steps. For details, see Get Suggestions on Procedure Steps.

- Suggesting procedures to add to work order details. For details, see Get Procedure Suggestions for a Work Order.

MaintainX CoPilot optimizes your workflow by suggesting ways to enrich your work orders based on your continued interaction with it.

Generate Work Order Summaries

After you complete a work order, MaintainX CoPilot can assist you by reviewing work order details, including procedure details if any are attached, and your written or recorded completion notes. For details, see Add a Summary to a Work Order.

As you add work order summaries to MaintainX CoPilot-enabled assets, MaintainX builds a knowledge base that MaintainX CoPilot uses to provide better, data-driven answers to questions about your assets.

Create an Internal Knowledge Base

Continuously interacting with MaintainX CoPilot throughout the work order lifecycle enables the creation and enrichment of your organization’s knowledge base. This knowledge base accelerates daily workflows and supports more accurate, data-driven answers to asset-related questions.

Work Order Concepts

Here are some important concepts about work orders.

Preventive vs. Reactive Work Orders

Work orders can be Preventive or Reactive.

- Preventive work orders are for scheduled maintenance or other recurring scheduled work. Most of the time, you set them up as chains of recurring work orders.

- Reactive work orders are for responding to one-off events like machine breakdowns or urgent repairs. Most of the time, reactive work orders are not recurring.

Work Order Chains/Recurrence

A work order chain is a series of recurring preventive work orders to perform the same maintenance task at regular intervals. For example, you can create a work order chain for daily inspection of a machine. For more information, see Create a Work Order.

Work Order History

Work order history exists when you create work orders for a MaintainX entity such as Locations or Assets. This data shows how many work orders are created and completed on the entity within a selected date range. This information lives in the details pane of the selected items of the entity that you want the work history for.

Work Order Summary

A work order summary is a written or recorded note you add to a work order to document how you completed it. The summary functionality is available for work orders with and without a MaintainX CoPilot-enabled asset.

Work order summaries are based on work order details, including procedure details if any are attached, and your written or recorded notes.

With work order summaries, you build a knowledge base that MaintainX CoPilot uses to provide better, data-driven answers to questions about your assets. You can refer back to this knowledge base every time you ask MaintainX CoPilot about an asset and see from which sources its response was extracted, e.g. work order summaries or asset manuals.

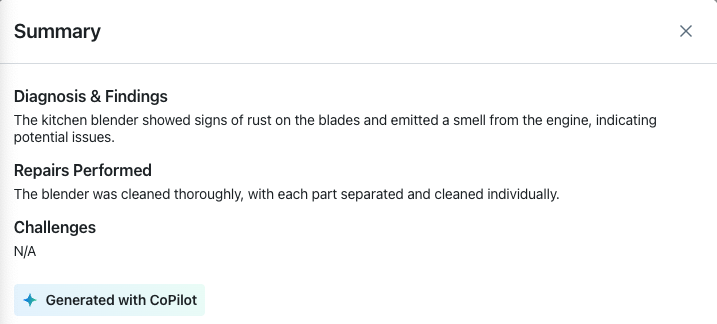

When you complete a work order, you can record or write a note that describes the work you did. MaintainX CoPilot will:

- Analyze your note.

- Generate a summary.

- Attach the summary to the asset's internal knowledge base, which MaintainX CoPilot reuses to answer new questions about the asset.

- Add the summary to your work order details.

To further your understanding of the note and guide you in the creation of maintenance tasks, MaintainX CoPilot automatically organizes your note into three sections:

- Diagnosis & Findings: A summary of your note, highlighting root causes, observations, and key insights.

- Repairs Performed: A list of repairs you performed.

- Challenges: An account of the difficulties you encountered while executing the work order.

The generated summary is then shared with your organization and made available in the MaintainX applications.

Voice notes are limited to 2 minutes. MaintainX discards the voice note recordings after it generates the summaries.

You can add a work order summary in a language different from your organization's display language. MaintainX CoPilot will translate your note accordingly. Administrators can configure the organization's display language in the organization settings. For details, see Organization Settings.

You can ask MaintainX CoPilot to translate your note into another language. MaintainX CoPilot defaults to English if the selected translation language is not supported.

You can access summaries attached to your assets and work order.

In the MaintainX CoPilot-enable asset or work order details, do the following:

- Select (MaintainX CoPilot).

- Select (Sources).

- In the Source type drop-down, select Work order summaries.

Corrective Actions

A corrective action is a work order created manually or automatically in response to an event or a condition such as Anomaly Detection or through a specific procedure action in a work order chain. For more information, see Trigger a Work Order.

Resource Planning

MaintainX has a dedicated view for resource planning. You can use the Workload View to plan, schedule, and assign work from work orders. You can see users' capacity, which helps you balance your team's workload. For more information, see About Resource Planning.

Time and Cost Tracking

While completing a work order, users can record time and work order costs in the Time and Cost tracking section located in the work order details page. This feature shows Administrators how many units of a part are in stock, time spent on a specific asset, and other costs related to a specific work order. You can export this data through the Reporting module. For more information, see Create a Work Order.